In industrial operations where vacuum generation and thermal control are critical, long-term reliability and operating cost reduction are constant priorities. Many facilities struggle with frequent maintenance, complex mechanical systems, and rising energy expenses. This is where Steam Jet Ejector Vacuum Systems offer a practical and time-tested solution. Designed to operate using steam energy rather than moving mechanical parts, these systems deliver dependable performance while minimizing operational complexity. At Croll Reynolds, steam-driven process equipment is engineered to help industries achieve stable operation, lower maintenance demands, and measurable cost savings over the life of the system.

Understanding Steam Jet Ejector Technology

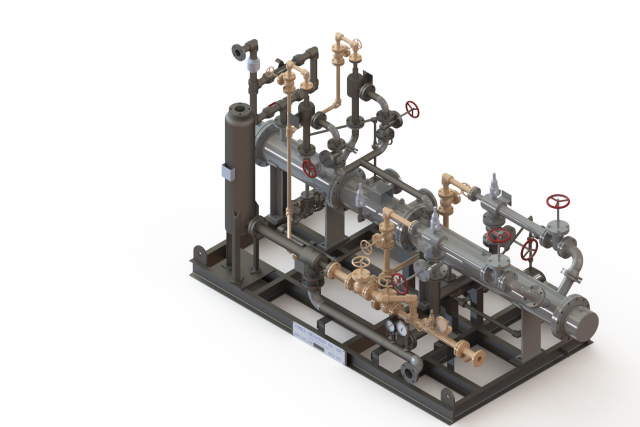

Steam jet ejector technology operates on a simple yet highly effective principle: high-pressure motive steam expands through a nozzle, creating a low-pressure zone that entrains gases or vapors from a connected process. The mixture is then compressed and discharged without the need for rotating equipment or electrical drives. This direct-use energy approach eliminates mechanical inefficiencies and reduces the number of failure points. Because the operating principle relies on fluid dynamics rather than mechanical motion, steam jet ejectors maintain performance consistency even under fluctuating process conditions.

Eliminating Mechanical Complexity to Reduce Maintenance

One of the most significant contributors to high operating costs in vacuum systems is mechanical wear. Pumps, seals, bearings, and lubrication systems require constant attention and periodic replacement. Steam jet ejector systems eliminate these components entirely. With no moving parts, there is virtually nothing to wear out during normal operation. This dramatically reduces maintenance frequency, spare parts inventory, and unplanned downtime. The result is a system that can operate continuously for extended periods with minimal intervention, making it ideal for demanding industrial environments.

Durability in Harsh Industrial Conditions

Industrial processes often expose equipment to corrosive vapors, high temperatures, pressure fluctuations, and fouling conditions. Steam jet ejectors are well-suited to these challenges due to their robust construction and material flexibility. Fabricated from carbon steel, stainless steel, or high-alloy materials, ejectors can be tailored to withstand aggressive chemical environments. Their simple internal geometry prevents buildup and erosion, ensuring long service life even in severe applications such as chemical processing, refining, and pulp and paper production.

Energy Utilization and Operational Efficiency

While mechanical vacuum systems rely on electricity and complex controls, steam jet ejectors use readily available process steam. In facilities where steam is already generated for heating or processing, ejectors integrate seamlessly into existing infrastructure. This efficient energy utilization reduces reliance on electrical equipment and lowers total energy costs. Additionally, steam jet systems handle wide turndown ratios without performance instability, maintaining efficiency across varying operating loads without requiring complex control mechanisms.

Process Stability and Consistent Performance

Operational disruptions often occur when vacuum systems fail to maintain consistent pressure levels. Steam jet ejectors deliver stable vacuum performance because they are unaffected by mechanical degradation. Their ability to operate reliably under variable flow rates and process conditions makes them especially valuable in applications such as distillation, evaporation, drying, and gas removal. Consistent vacuum levels improve product quality, process efficiency, and downstream equipment performance, leading to long-term operational cost reductions.

Simplified Installation and Retrofit Capability

Another advantage of steam jet ejector technology is its adaptability. These systems can be installed in new plants or retrofitted into existing process lines with minimal structural modification. Their compact design and lack of rotating equipment simplify layout planning and reduce installation time. For facilities upgrading aging mechanical vacuum systems, steam jet ejectors provide a straightforward replacement option that immediately lowers maintenance demands while improving reliability.

Reduced Downtime and Long-Term Cost Savings

Downtime is one of the most expensive challenges in industrial operations. Equipment failures not only halt production but also increase labor and repair expenses. Steam jet ejectors significantly reduce downtime risk due to their rugged design and passive operation. With fewer components subject to failure, operators can focus on process optimization rather than equipment troubleshooting. Over time, the combined savings from reduced maintenance, lower energy consumption, and improved reliability result in a lower total cost of ownership.

Conclusion

For industries seeking dependable vacuum solutions that deliver long-term value, Steam Jet Ejector Vacuum Systems provide a compelling alternative to mechanical technologies. Their durability, minimal maintenance requirements, and ability to operate efficiently in demanding environments make them an ideal choice for cost-conscious operations. By leveraging proven steam-driven principles, Croll Reynolds continues to support industrial clients with reliable process solutions that reduce operational expenses while enhancing system performance and longevity.

MOST COMMENTED

Vacuum Equipment Manufacturers

Reducing Operational Costs with Durable, Low-Maintenance Steam Jet Ejector Technology

Business consultant

How to Choose the Right Outsourcing Partner for Long-Term Business Success

Travel and Tourism

Why Private Car Rentals Are the Most Convenient Way to Travel Around Zanziba

Corporate Gifts and Promotional Products

The Role of Promotional Bags in Modern Corporate Gifting Strategies

Wholesale distributor

Why the Best Gutter Covers Are Essential for Maintenance-Free Gutters

Health

The Role of Private GP Clinics in Early Diagnosis and Long-Term Wellness

Junk removal

Häufige , die bei der Nutzung von Müllentsorgungsdiensten für Wohnungs- oder Büroauflösungen vermieden werden sollten